Choosing the right cutting board for your kitchen can be a bit of a challenge, especially with so many different materials and styles to choose from. One common decision you’ll need to make is between end grain and face grain boards. Although both types of boards can be effective for cutting, chopping, and slicing, they offer distinct advantages and disadvantages, and choosing the right one will depend on your specific needs and preferences

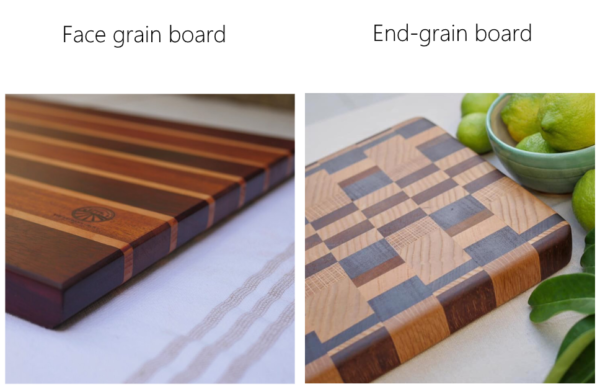

End grain boards are made from small blocks of wood that have been glued together with the end grain fibers exposed on the surface. This design creates a cutting surface that is soft on knife blades and has a natural resistance to moisture and bacteria. The fibers also have a unique self-healing property, which allows them to compress and bounce back when cut, effectively closing up any grooves or scars.

Face grain boards, on the other hand, are made from large planks of wood that have been sanded smooth and sealed. Because of this, face grain boards show the most grain and often have a very striking look.

When compared to end-grain, the surface of face grain boards is harder, making them more prone to scarring over time. This therefore makes face grain boards less favorable for heavy chopping in industrial kitchens.

Ultimately, the choice between end grain and face grain boards will depend on your specific needs and preferences. End grain boards are ideal for those who want a soft, durable, and easy-to-maintain surface, while face grain boards are better for those who need a harder, more durable surface that will hold up to heavy use. Regardless of which type of board you choose, it’s important to take good care of it, and to replace it when necessary, in order to ensure optimal performance and longevity.